快T系列

联系我们

Contact Us

广州方中化工有限公司

广东方中高新材料有限公司

电话:020-82327221

传真:020-82327331

24小时技术服务专线:18820031519

地址:广州科学城神舟路768号7栋

厂址:广东英德英红园新材料基地

快T、琥珀酸二异辛酯磺酸钠、OT75

发布时间:2022/1/19 10:43:14 点击量:

|

用法与用量 |

快T系列表面活性剂的典型应用

快T系列表面活性剂除了是一种优异的润湿剂外,也可用于乳化、稳定和分散等应用。在以下几个有代表性的应用中,表现出特殊性能:

印刷油墨和上光油

快T系列表面活性剂,作为一种润湿和流平剂,广泛地应用于水基印刷油墨配方中,具有以下特性:

· 快速和显著地降低配方的表面张力。

· 改善基材的润湿性能,从而提高附着力、光泽和颜色细度。

· 改善流动性能,可获得均一涂层。

· 快速润湿与非常快的印刷速度相容。

乳液聚合

快T系列表面活性剂可作为主或次乳化剂,后添加剂应用在许多乳液类型的生产,特别在酸或丙烯酰胺改性的丁苯乳液中。作为乳液体系用的乳化剂,它具有下列的表现性能:

· 低CMC,在低用量情况下,能有效地产生颗粒。

· 能生产非常低的颗粒尺寸和窄的颗粒分布。

· 用快T系列表面活性剂生产的乳液具有非常低的凝结物、高转化率和高分子量。

· 在丁苯乳液体系中,作为次乳化剂。

在各类乳液中,包括纯丙、苯丙、醋丙、丁苯乳液,作为后添加剂,在降低表面张力和改善流动和流平方面具有非常优异的功效。

其它应用

· 纺织和造纸:作为润湿和分散剂非常有效。

· 涂料配方:提供优异的流动和流平性能,改善涂料的润湿和附着力。与有机溶剂优异的溶解性使得它可与各种添加剂和配方相容。

· 干洗:由于非常好的润湿、分散、渗透和乳化能力,使得它在液体干洗中非常有效。另外,在玻璃窗、汽车挡风罩等应用中也同样非常有效。

· 农化产品:被广泛地用于易分散润湿、可流动的农药粉末制剂中。

· 抗静电:可作为抗静电剂/柔软剂。

· 有机/碳氢体系:在广泛的有机/碳氢体系中,作为润湿/溶解/分散剂是非常相容和有效的。

· 可作为许多基材的润湿剂,如金属、玻璃、塑料等。

用法用量:作为润湿分散剂建议用量0.5-20%。

为获得最佳性能,应在分散前添加,使用量在很大程度上取决于应用体系,建议用户在使用前通过实验确定最佳添加量。如果出现冻融现象,建议在使用以前进行充分搅拌。

|

安全、储存和技术服务 |

在一般储存环境置于密闭容器中,避免阳光直射。室温储存稳定性:至少 24 个月。

本产品使用安全,但不宜与皮肤直接接触。使用前适当防护如戴手套和眼镜; 本品溅到眼睛或皮肤上,应立即用大量清水冲洗,并视情况就医。

对于意外情况的处理,以及有关环保、毒性、运输、储存等的资料,请查阅另外的产品安全数据资料。

|

包装 |

25kg/桶;200kg/桶。

|

Features |

|

Ion type:Anion |

|

|

Chemical:Sodium dioctyl sulfosuccinate |

|

|

CAS No.:577-11-7 Molecular Formula:C20H37O7NaS |

Description: An excellent wetting agent and emulsifier, characterized by its very quick migration to the interface. Its surface modifying properties can be utilized to reduce surface tension and to increase absorbency and penetration.

Fast T: 50% content, universal fast penetrant T.

|

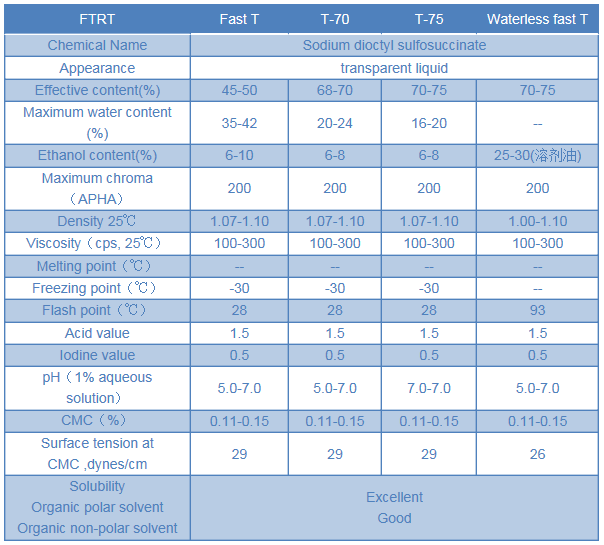

Physical and Chemical Properties |

|

Usage and Dosage |

Typical application of Fast T series surfactants

In addition to being an excellent wetting agent, Fast T-series surfactants can also be used in applications such as emulsification, stabilization and dispersion. In the following representative applications, it shows special performance:

Printing inks and varnishes

Fast T-series surfactants, as a wetting and leveling agent, are widely used in water-based printing ink formulations with the following characteristics:

· Quickly and significantly reduce the surface tension of the formulation.

· Improves the wetting properties of the substrate to improve adhesion, gloss and color fineness.

· Improve flow properties for a uniform coating.

· Fast wetting is compatible with very fast printing speeds.

Emulsion polymerization

Fast T-series surfactants can be used as primary or secondary emulsifiers,or post-additives in the production of many emulsion types, especially in acid or acrylamide-modified styrene-butadiene emulsions. As an emulsifier for emulsion systems, it has the following performance properties:

· Low CMC, which can effectively produce particles at low dosages.

· Can produce very low particle sizes and narrow particle distribution.

· Emulsions produced with Fast T-Series surfactants have very low condensate, high conversion and high molecular weight.

· As a secondary emulsifier in the styrene-butadiene emulsion system.

Among the various types of emulsions, including pure acrylic, styrene-acrylic, vinegar-acrylic, and butylbenzene emulsions, as post-additives, have excellent effects in reducing surface tension and improving flow and leveling.

Other applications

· Textile and paper: very effective as a wetting and dispersing agent.

· Coating formulation: Provides excellent flow and leveling properties to improve coating wetting and adhesion. Excellent solubility with organic solvents makes it compatible with a wide range of additives and formulations.

· Dry cleaning: It is very effective in liquid dry cleaning due to its very good wetting, dispersing, penetrating and emulsifying properties. In addition, it is also very effective in applications such as glass windows and car windshields.

· Agrochemical products: widely used in easily dispersed, wettable, flowable pesticide powder formulations.

· Antistatic: It can be used as an antistatic agent/softener.

· Organic/hydrocarbon systems: Very compatible and effective as a wetting/dissolving/dispersing agent in a wide range of organic/hydrocarbon systems.

· Can be used as a wetting agent for many substrates, such as metal, glass, plastic, etc.

Reference dosage:0.5-20%

For best performance, it should be added before dispersion. The amount of use depends largely on the application system. It is recommended that the user determine the optimum amount by experiment before use. If freezing and thawing occurs, it is recommended to stir well before use.

|

Storage and Handling |

Keep it in a closed container in a normal storage environment and avoid direct sunlight. Storage stability at room temperature: at least 24 months.

This product is safe to use, but should not be in direct contact with the skin. Proper protection before use such as wearing gloves and glasses; If this product splashes on your eyes or skin, rinse immediately with plenty of water and seek medical advice as appropriate.

For information on accident handling, as well as information on environmental protection, toxicity, transportation, storage, etc., please refer to additional product safety data.

|

Package |

25kg/drum;200kg/drum